Automatic Hydraulic Bollard Controller

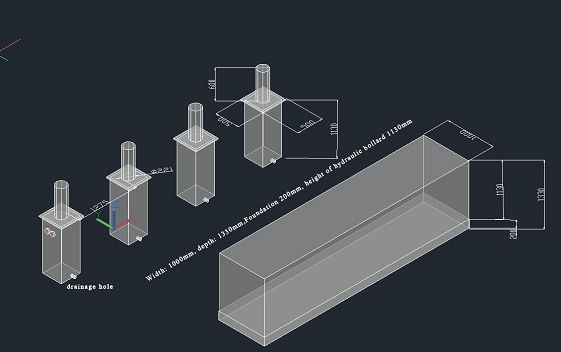

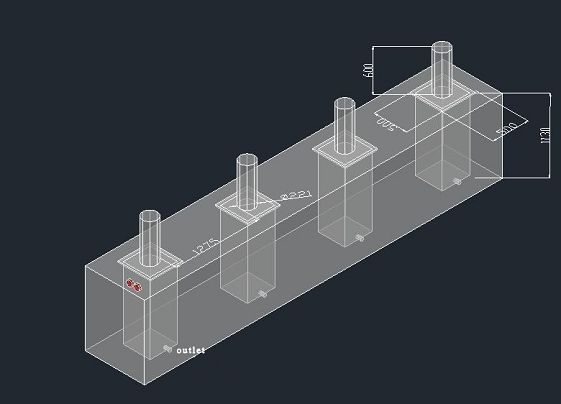

In the entrance and exit, please dig a square groove (long as your requirment* width 1000mm* depth 1330mm).

Foundation

In the entrance and exit, please dig a square groove (long as your requirment* width 1000mm* depth 1330mm).

Drainage System

Fill 200mm of concrete at the bottom of the square groove, ensure that the ground is level. At the bottom of the lifting column frame, all the surfaces of the underlying concrete can be contacted, so that the entire frame can be stressed. And at the middle of the lower part of the tank, keep a PVC60# for drainage.

The Drainage Method

1. If the terrain is relatively low. Use artificial drainage or electric pumping mode, need to dig a small pool near the column, regular manual and electric drainage.

2. If the terrain is relatively high. Use the natural drainage mode to connect directly to the sewer.

Controller mounting and lifting column rack connection

1. The controller is installed in the operating room, connected to the lifting column frame through the line pipe, all lines must go inside the pipeline (PVC pipe protection)

2. After determining the installation position of the lifting column frame, when excavating the foundation, it is necessary to arrange the control line and the trench according to the topography of the installation site, and ensure that it is safely buried without damaging other underground equipment. Mark in the proper position to avoid damage to the pipe line during other construction operations, causing unnecessary losses.

Commission Test

1. After the pipeline connection is completed, it should be re-examined to confirm that there is no error.

2. Connect the 220V three-phase power supply

3. Start the motor idling and check if the motor rotation is correct. If it is not correct, please change the motor live wire 1 and the motor fire wire 2. And then proceed to the next step after normal operation.

4. Check if the pressure relief solenoid valve is normal and check if the LED light is normal.

5. After confirming that the hydraulic lifting column is working normally, cast concrete around the main machine and fix the lifting column.

13613060393

13613060393